On the planet of electronics and contemporary innovation, the relevance of printed circuit card (PCBs) can not be overstated. These intricate parts create the foundation of basically every electronic gadget, from computers and smartphones to household devices and medical devices. A PCB, often referred to as a motherboard, gives the important framework for attaching various electronic parts through conductive tracks etched onto non-conductive substrates. Among the many kinds of PCBs, the rigid-flex circuit boards attract attention as an amazing advancement. These are hybrid boards that incorporate the most effective characteristics of flexible and rigid PCBs, permitting for vibrant layouts that can bend and twist without sacrificing structural integrity. This adaptability makes rigid-flex circuits particularly attractive for applications where space is limited, such as in mobile phones and wearables.

The production of PCBs, specifically in high-density interconnect (HDI) configurations, has evolved as the need for smaller sized, quicker, and much more efficient electronics increases. HDI PCBs include finer lines and areas, in addition to smaller vias, which permit higher component density. This is specifically necessary in today's busy tech landscape where performance renovations are continuously gone after. To make these sophisticated boards, companies frequently employ innovative techniques such as microvia modern technology, which includes creating really little vias through laser drilling approaches. The advantages of microvias include boosted signal speed and reduced electro-magnetic interference, therefore enhancing the total functionality of the electronic tools they support.

Collective endeavors with printed circuit manufacturers are essential in making certain that PCB styles transition efficiently from conceptual phases to real products. These manufacturers specialize in different aspects, consisting of PCB assembly and fabrication. They make use of products like FR-4, a flame-retardant epoxy resin, which is commonly related to for its balance of performance and cost-effectiveness. In the world of high-performance applications, variations such as Rogers material, Megtron 6, and Megtron 7 are often utilized for their premium dielectric residential properties and high-frequency efficiency. Subsequently, printed circuit board assembly (PCBA) becomes a vital step in the process where various elements are soldered onto the PCB in accurate setups to guarantee ideal operation.

Quick turnaround PCB prototyping services have actually acquired popularity as services make every effort to bring their items to market swiftly. With the raising schedule of fast-turn PCB services, the obstacles to prototype growth have actually been substantially decreased, allowing an atmosphere of advancement.

Flexible printed circuit card (FPCBs) are one more impressive category that has amassed focus as a result of their special abilities. These boards are developed to be ultra-thin and light-weight, supplying the capacity to flex, fold, or twist without endangering performance. This flexibility makes them an ideal selection for applications in numerous areas, including consumer electronics, auto, and medical devices. FPCBs can additionally assist streamline assembly procedures, as their design allows for a more portable type element, which often causes fewer link points and possible failure settings.

Several manufacturers concentrate on creating flexible circuits, typically incorporating innovative materials and production methods to boost performance and dependability. Thermal monitoring, for example, plays a vital role in PCB design, particularly in electronic items that run under high loads. Engineers need to take into consideration materials with excellent thermal conductivity, such as heavy copper PCBs, which assist dissipate warm successfully. Advancements like the back drill process are made use of to optimize signal integrity by eliminating excess material around vias, hence removing the potential for signal degradation.

Understanding regarding different facets such as circuit card assembly, which consists of the process of soldering components onto a PCB, flex circuit connectors can significantly impact the end item's quality. In addition, using devices and software application designed for PCB layout and simulation can substantially enhance the design process, allowing designers to quickly change prototypes based on testing end results.

Variations in PCB types such as 2-layer, 4-layer, and multi-layer boards are each matched to details applications based upon their complexity and the variety of components that need to be integrated. Four-layer PCBs supply increased directing capacities, essential for a lot more innovative electronics. These boards help in handling signal stability and give ample area to path traces extra effectively, making sure even more dependable performance in every little thing from smartphones to complicated commercial tools.

Contract PCB assembly services have actually become a crucial source for companies doing not have the internal capabilities to handle complex assembly processes. These services typically include detailed assistance varying from design examination to full-blown production, supplying services with the adaptability they require to satisfy varying demands. By partnering with well established get more info manufacturers, services can take advantage of expertise in locations such as HDI formats, microvias, and multilayer PCBs, consequently broadening their product offerings without spending greatly in equipment and labor.

Choosing the appropriate products for PCB production is essential, and considerations often consist of the ecological standards relevant to their usage, including UL ratings, such as 94V-0, which concerns terminate retardancy. Manufacturers need to remain notified about conformity policies to ensure that their items satisfy safety criteria while likewise performing ideally in their intended application settings.

The combination of superhigh frequency (RF) innovation into PCBs is an additional area seeing boosted relevance, especially with the surge of wireless interaction devices. RF PCBs should be meticulously developed, with factors to consider for insusceptibility control and reduced signal loss as a result of the high frequencies included. This field of expertise requires understanding of RF circuit design and might involve in-depth electro-magnetic simulations as designers function to achieve optimal performance in portable kinds.

As technology remains to check here progress, manufacturers are significantly adopting automation and advanced fabrication processes to improve performance. Technologies such as automated optical examination (AOI) and surface area mount innovation (SMT) are currently common techniques, permitting for high-speed assembly and consistent quality control. Innovations in PCB manufacturing also include brand-new products and strategies, such as the usage of embedded innovation where components are embedded directly within the layers of the PCB, further saving room and boosting efficiency.

Finally, the printed motherboard market constantly adapts to changing demands and technological advancements, mirroring the vibrant landscape of electronics. Whether with PCBA, flexible circuits, or fast-turn prototypes, the designs, materials, and procedures connected with PCBs are crucial fit the future of electronic tools. Manufacturers who remain at the center of these advancements not only boost their affordable side however also make it possible for the growth and development of sophisticated innovations that define modern life. With the ever-increasing intricacy of circuits and the demand for reliable, high-performance services, the PCB industry remains a keystone of technical development, driving the means we interact with tools and eventually connecting our physical and digital worlds.

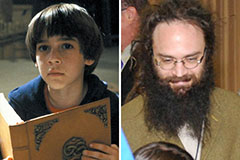

Barret Oliver Then & Now!

Barret Oliver Then & Now! Bradley Pierce Then & Now!

Bradley Pierce Then & Now! Daniel Stern Then & Now!

Daniel Stern Then & Now! Julia Stiles Then & Now!

Julia Stiles Then & Now! Loni Anderson Then & Now!

Loni Anderson Then & Now!